Manufacturing DIY Plastic Blocks

Fundraising campaign by

rdbotha112

-

US$0.00Donated So Far

Campaign Story

Our campaign:

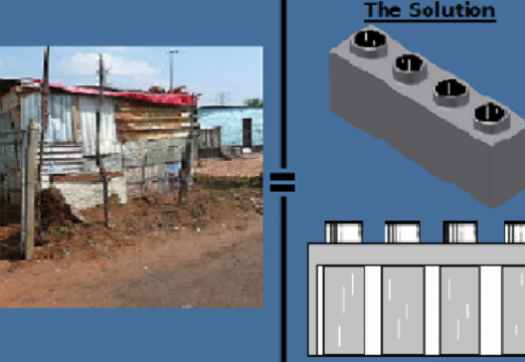

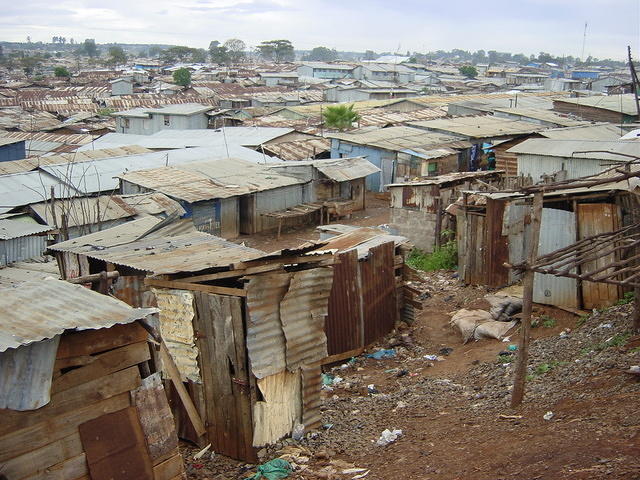

It is estimated that over 1 BILLION people are currently living in slums and the number expects to grow to over 2 BILLION by the year 2030. The sadness is that it is mostly in inhuman condition. Any upset (fire, mudslides, bad weather, etc) leads to traumatic upset in people’s lives and leaves them in very difficult circumstances. These are poor communities and either rebuilding or repairing a “shack” after a disaster is out of reach for most of the people and is done with inferior materials. Circumstances usually go from bad to worse. Building methods are complex and building materials expensive. Informal settlements are build from bits and pieces.

It is important to us to drive this campaign to find easy, cheap DIY alternative building methods for people to build livable, durable, neat housing, “ONE BLOCK AT A TIME”.

Short Summary of my skills and work experience.

My extensive work experience was gained in highly competitive environments in Houston, Singapore, South Africa, Angola and Nigeria at major Industries namely Oil, Iron & Steel, Electrical Distribution, Plastic Manufacturing, Gas Processing (Ammonia and Methanol) and relate to construction and industrial environments. I am experienced in Project Management and Supervision. Revenue Cycle Management. Personnel and Admin, Marketing, IT Billing, Revenue and Operational Management. Safety Practices, Material control, cost control, shutdown planning and commissioning. Electrical design, maintenance and installation of PLC, AC Machines and Control Systems, DC Control Equipment and Variable Speed Drives, Lighting Systems, Hazardous Location Equipment, HT Electrical Distribution, Electronics, Refrigeration and Appliances, Hydraulics, Mechanical Systems and Basic Welding. Training of management, technical and process staff by means of Competency and Outcome Based Training. Module and Maintenance Manual Development.

What is the product about?

- Blocks that fit into each other in a pipe like manner. This gives the benefit of creating internal piping throughout the construction.

- This piping can be used for water, electricity or waste.

- Piping can also be filled with soil or cement for insulation and/or weigh.

- Blocks can be bound together by other means eg. pvc glue, wire, etc.

- Chambers / cavities can be filled with various materials for additional insulation if necessary.

- Blocks will come in single or double configuration and variable sizes to suit every need.

Your contribution:

Contributions will change the lives of people all over the world. You only need to look at the news to see the suffering of people from Brazil to the Philippines, from Africa to America. It will also benefit the DIY enthusiast to built that home, shed, home extension, or whatever the DIY mind can think up without the complex building methods available (Cement, sand, water, bricks, tiles, steelwork, etc).

Your contribution will help to develop the product from design to manufacturing and distribution while creating opportunities for people to empower themselves.

Your contribution will go to the following:

- Final development and fine tuning.

- Prototypes.

- Building of molds.

- Fabricating blocks.

- Marketing and distribution.

Our ultimate goal is to use recycled plastic to fabricate our building blocks. This will allow us to help the environment and the people.

What will happen with the funds if we don't reach the entire goal?

Fewer Contributions will only mean a smaller start. All the remaining funds after development will be used to make a difference towards disadvantaged communities by means of various outreaching projects all over the world.

What You Get:

Your contribution will make you the first receiver of the product in your country to build a standard tool shed.

Alternatively you have the choice to donate the material in your name to a disadvantage person.

Think what DIY projects you can undertake with a product like this?

Challenges:

- Within the development stage we will have the product registered and approved as a building method and building product.

- To get the building method and product accepted by the community we will build prototypes within communities to demonstrate the concept and advantages.

Other Ways You Can Help:

If you can't make a monetary contribution please help us in the following ways:

- Please get the word out in any way you can, a good tool to use is Facebook / Twitter, etc.

- Please identify communities in need for our initial campaign.

- Tell all your friends and family about this, and give out the direct address to this site.

Rewards

Organizer

- rdbotha112

No updates for this campaign just yet