Fast Pyrolysis Reactor-Ultimate Bioenergy Solution!

Fundraising campaign by

Ivan Tosic

-

€0.00raised of €500,000.00 goal goal

Campaign Story

ECOPOWER Trust invites you to participate in development of Fast Pyrolysis Reactor (FPR) from prototype to “State of Art” technology, with a vision and objective to launch manufacturing unit in Serbia that offers FPR worldwide, as the ultimate device for bioenergy production!

Bioenergy

Bioenergy is energy derived from organic material (biomass) – it can be used for power generation (such as electricity) and heat applications in all energy sectors including domestic, commercial and industrial purposes.

“In 2014, 16% of Europe’s energy supply came from renewable energy, with bioenergy contributing more than 60% of this share” - (Gustav Melin, President European Biomass Association)

Bioenergy from wooden biomass

|

Wooden biomass = forestry waste + wood processing waste. Wooden biomass = forestry waste + wood processing waste. |

Why Serbia?

|

General Overview |

Republic of Serbia has performed internationally recognised economical reforms and has become a proven investment destination in the South East European region due to:

|

|

Particular Overview

|

Forests Bioenergy production starts in forest! ECOPOWER selects the area of Tara Mountain as advanced forested area with preserved and most productive forest communities in Europe! Over 75% of the Tara Mountain surface area is covered by forests (15,426.91 ha), covering 34 different communities. BioRES Biomass Logistic and Trade Centres (BLTC) BLTC stands for Biomass Logistic and Trade Centres, which are regional hubs linking wood supply from forest owners, saw mills and other wood producers with demand from bulk and small buyers. One of the largest established BLTC in Serbia is located at Tara Mountain, under management of ECOPOWER close associate! |

Successful bioenergy production directly depends on biomass logistic – after successful development of BLTC in accordance with BioRES criteria, the next step is development of unique device manufacture in close neighborhood to BLTC that operates under attractive economical terms and conditions!

Bioenergy production methods

|

Burning |

Wood burnings can produce power, electricity, or heat. To produce power, wood can be burned in a boiler or a large combustion chamber in order to heat water and generate steam. The ash is the waste of the process, and requires a proper treatment. |

|

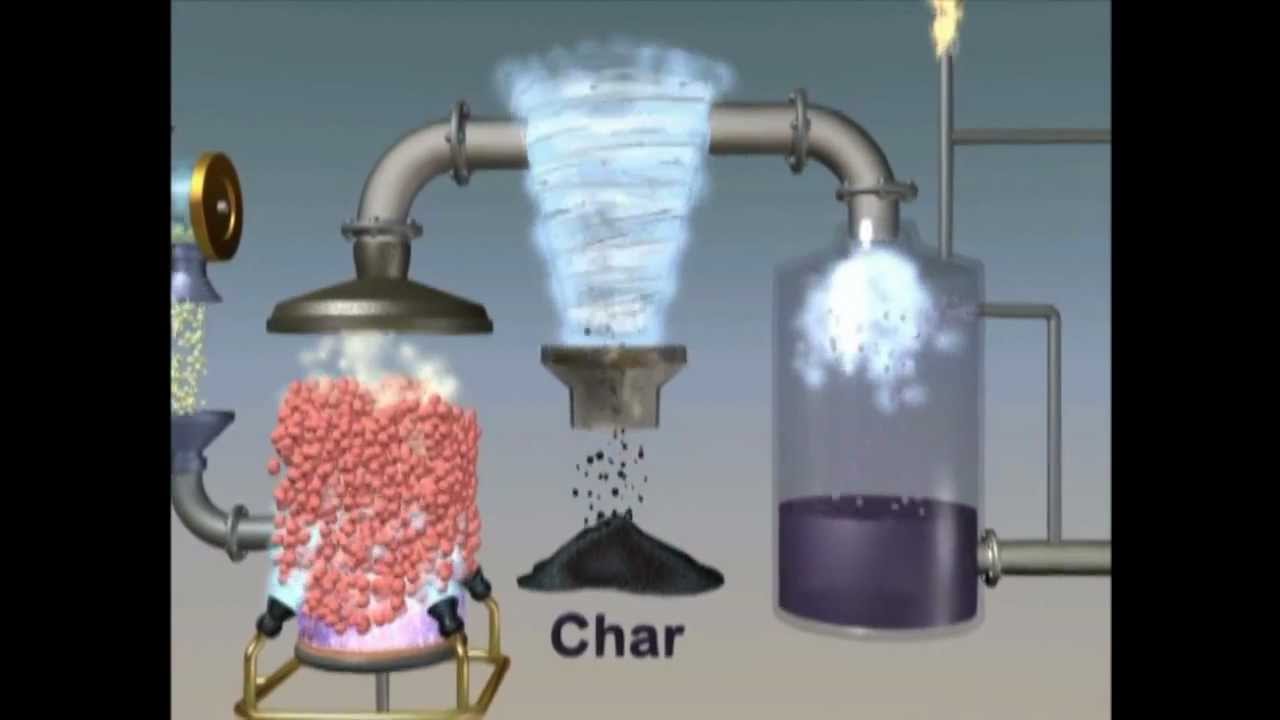

Pyrolysis

|

Pyrolysis is a process in which organic biomass are rapidly heated to 450 - 600 °C in the absence of air. Under these conditions, organic vapors or synthetic gases and charcoal are produced, and heat must be realized from pyrolysis device. All outputs of the process are commercial products and there is no waste! |

Pyrolysis method of bioenergy production from wooden biomass

|

The global tendency in respect of bioenergy production is Co-Generation or combined heat and power (CHP) production – it is the use of a heat engine or power station to generate electricity and useful heat at the same time.Pyrolysis method allows CHP production of electricity and heat from wooden biomass with higher commercial efficiency in comparison with CHP technical solutions based on burnings. |

So far, pyrolysis has not been widely used for treatment of wooden biomass, since there are plenty of CHP technical solutions based on burnings classified as “State of Art” – term that refers to the highest level of general development, as of a device, technique, or scientific field achieved at a particular time.

Pyrolysis VS Burning in General

|

Burnings |

Pyrolysis |

|

|

Capital Expenditures (CAPEX) per 1 MW of electricity installed power |

3.5 – 4 M € (Proven) |

2- 2.5 M € (Estimated) |

|

Hourly Fuel Consumption (Wooden Chips) Per 1 MW of electricity installed |

1.5-2 tons (Proven) |

0.8-1 ton (Proven) |

|

Ratio electricity/heat |

30/70 |

45/55 |

Pyrolysis VS Burning Simple Commercial Comparison

In order to illustrate commercial advantages of pyrolysis method, the following assumptions are taken:

- Analysed is performance per hour of CHP based on pyrolysis and burnings with 1 MW installed power of electricity: input is the same (wooden chips supplied by Serbian BLTC in the range of 1,000 km away), outputs are electricity, heat, and bio char (output of pyrolysis only!)

- Operational expenditures (OPEX) are not considered, although it is proven that pyrolysis suffers lower OPEX than burnings

- There is Serbian “Feed In” tariff concerning sale of electricity generated from wooden biomass (recently is 132.86 €/MWh)

- Income from heat sale is calculated under privileged terms and conditions: the rate of 20 €/MWh in order to boost the sale

- Income from sale of Bio Char (Charcoal) is calculated considering the recent market price in Serbia (300 €/t)

- Pyrolysis performance is assumed considering experimental performance results of Fast Pyrolysis Reactor (FPR) prototype measured and monitored by independent professionals.

| Burnings | Pyrolysis | |

| Input cost (120 € / ton) | 180 € | 120 € |

| Income from electricity sale | 132.86 € | 132.86 € |

| Income from heat sale | 60 € | 30 € |

| Income from charcoal sale | 0 € | 60 € |

| Profit per hour | 12.86 €

(7.14 %) |

102.86 €

(85.71 %) |

Why Pyrolysis?

- CAPEX is lower in comparison with “State of Art” technologies based on burning of biomass;

- Lower consumption of biomass – lower OPEX!

- No waste – all outputs are commercial products!

- Small or Medium sized consumers can afford pyrolysis based CHP plant – wider implementation range!

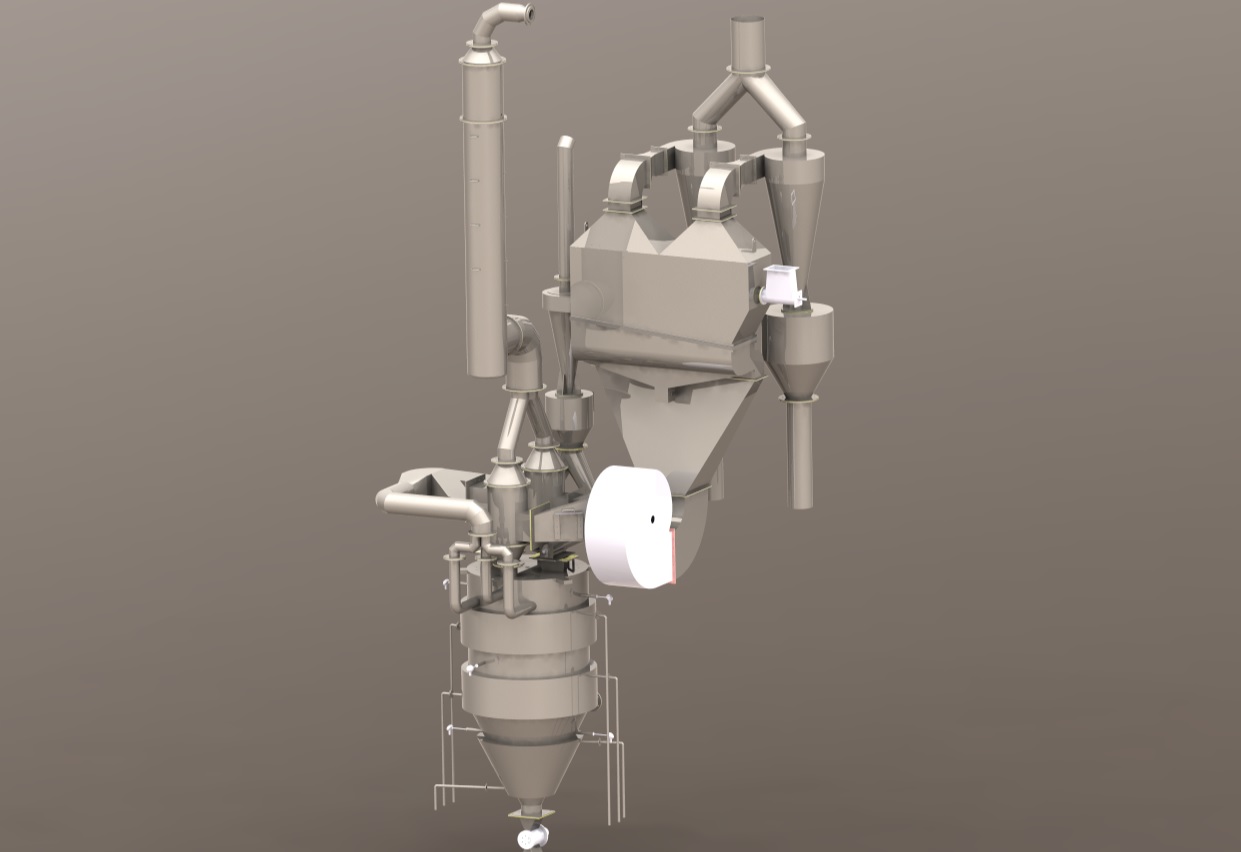

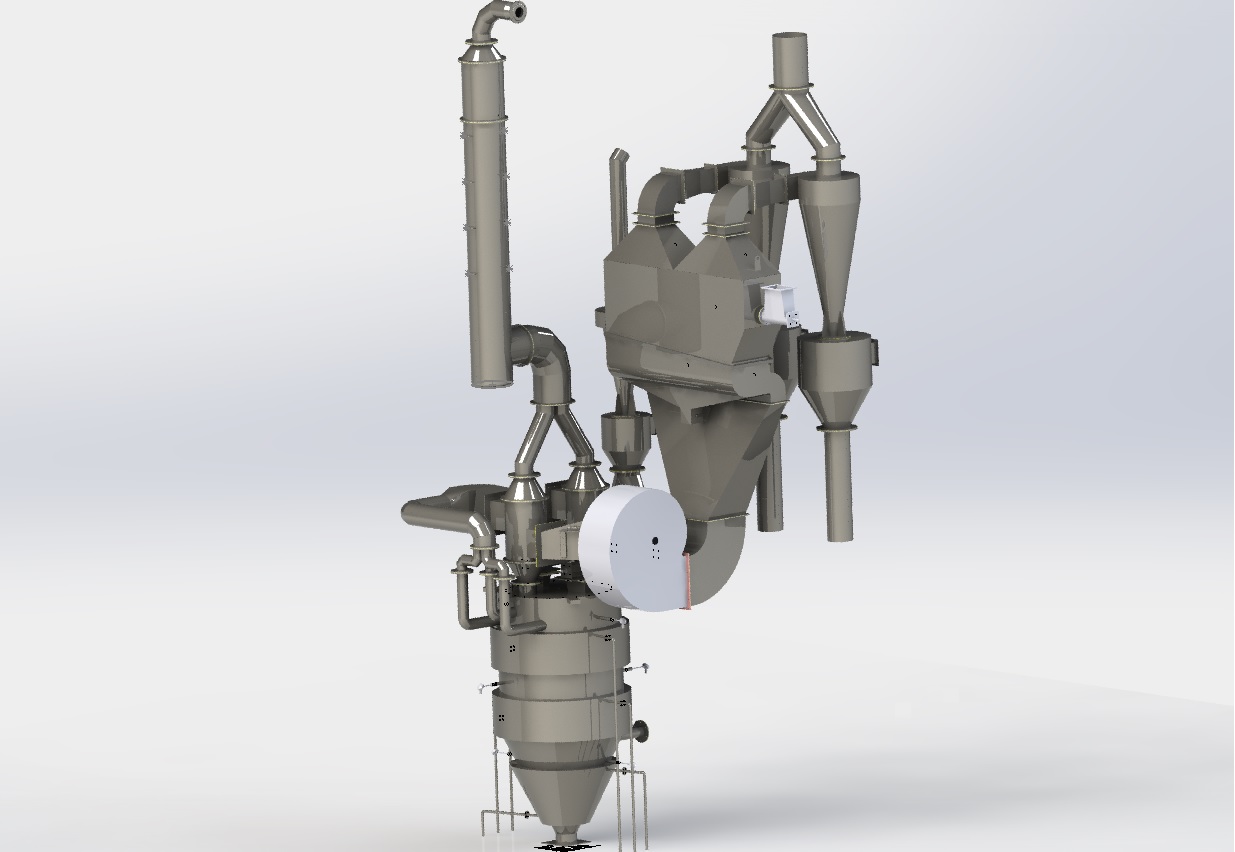

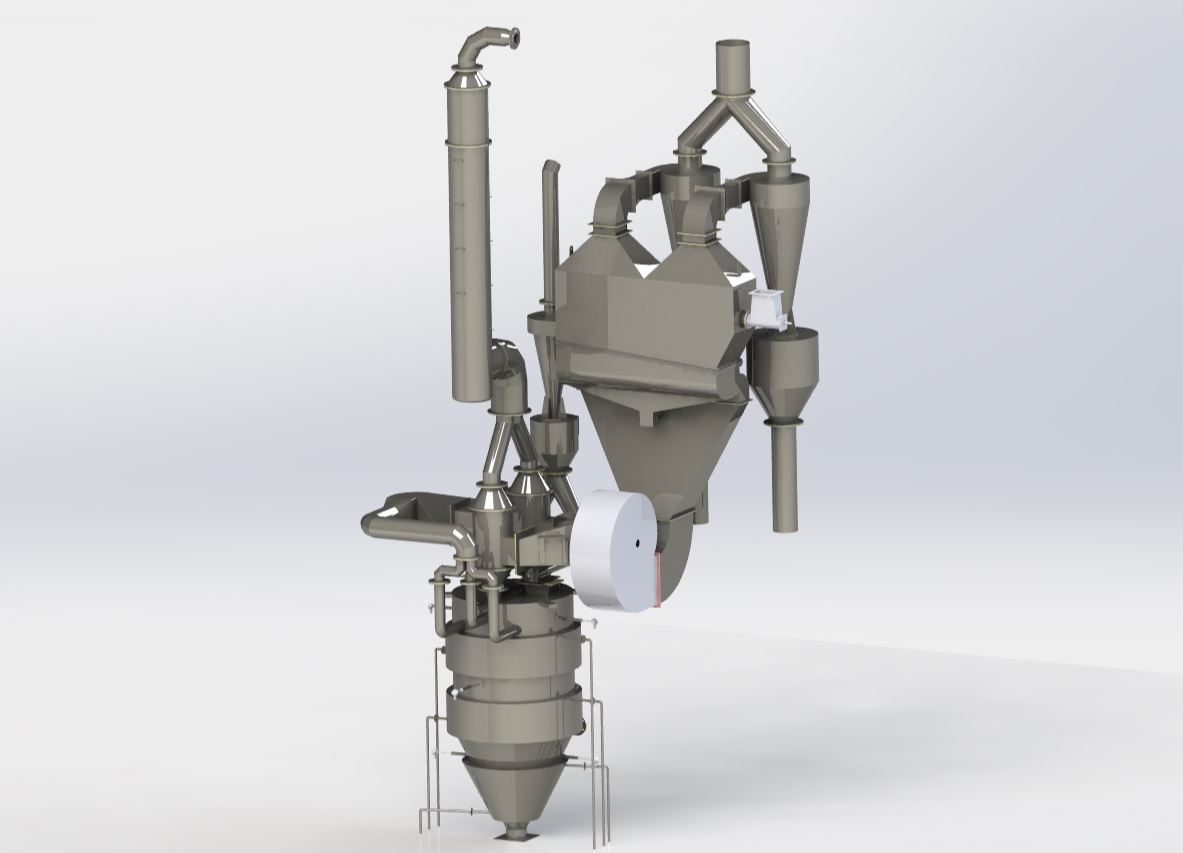

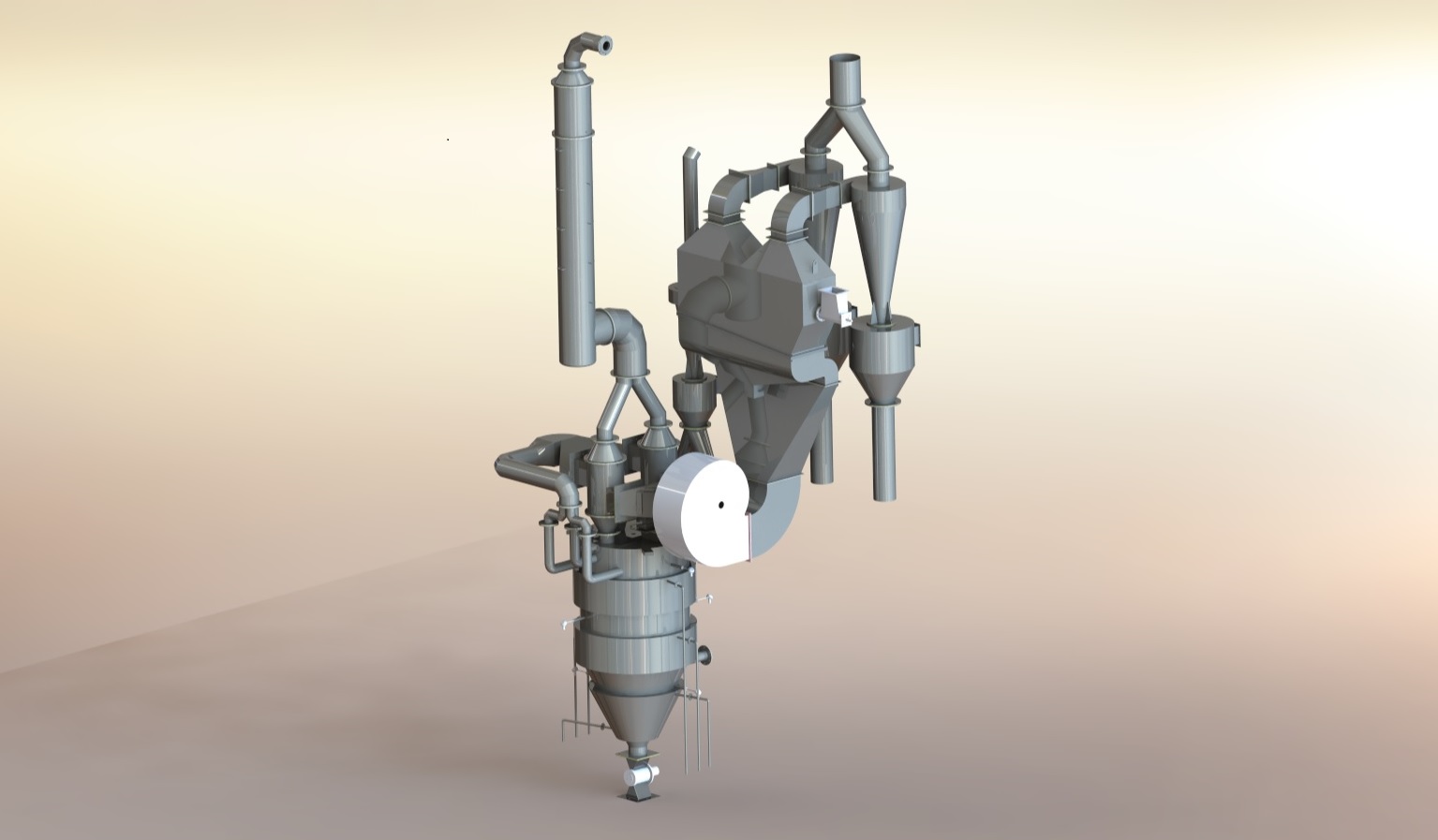

Fast Pyrolysis Reactor (FPR) Prototype

Fast Pyrolysis Reactor (FPR) prototype has been manufactured, installed and tested at Serbian BLTC and it confirms initial assumptions - pyrolysis is more efficient treatment of wooden biomass than burning:

|

|

|

FPR Wide Implementation

Measured results of prototype experimental performance indicate that FPR should be the basis for Co-Generation that serves energy requirements of:

- Wood processing plants – it is attractive solution since their cost of biomass is lower (generated on the site!)

- Small or Medium and Large Industrial Plants – adjusted FPR, or cascade installed FPR easily meets industrial energy requirements (from 0.5 MW and up of electricity installed power)

- ESCO providers (An energy service company is a commercial or non-profit business providing a broad range of energy solutions including designs and implementation of energy savings projects, retrofitting, energy conservation, energy infrastructure outsourcing, power generation and energy supply, and risk management).due to lower CAPEX and OPEX and higher return on investment!

Business Goal & Usage of Donated Funds

ECOPOWER Trust intents to create a Serbian company with objective develop FPR prototype to “State of Art” technology through:

- Additional testing of materials used in FPR prototype construction with objective to improve quality of synthetic gas, and mechanical corrections after testing – for this purpose, FPR prototype must perform minimum 2,000 hours under permanent measurement and monitoring;

- Improving of heat management system – at the end of pyrolysis, heat from reactor must be distributed to ending users, including FPR for next pyrolysis: this improvement requires design and implementation of cooling and distribution systems, which will distribute the heat in the required form (water, steam, air) to ending user;

- Design and implementation of automotive contro systeml – performance testing and improvement of heat management define algorithm for design and implementation of automotive control system (hardware and software) that will control the pyrolysis process;

- Certifications of FPR – applications and obtaining of CE Mark, TUV certificates, as well as ISO certificates;

- Industrial Design Copyright – completion of work on projects, drawings, manuals, construction guidance, quality certificates of FPR and outputs and their copyright registration under the name of the Company;

- Settlement of Manufacturing Unit in Serbia that should produce FPR and design Co-Generation plants in accordance with particular demands of investors/ending users in the region;

- Distribution – the Company should distribute FPR, Co-Generation plant and biomass from Serbian BLTC (where is necessary) to ending users in the region (in the range of 1,000 km away from BLTC) through intensive co-operation with ESCO providers, institutional investors (such as EBRD), and assistance to prospective applicants worldwide interested in settlement of their own manufacturing units through technology transfers (giving rights to use Industrial Design in exchange for royalty fees).

It is expected that goals defined as above will be achieved with expenditure of 500,000 EUR, and prospective donators are invited to donate in accordance with their potential considering offered rewards, in order to speed up FPR development from prototype to “State of Art” technology. Initiators have already invested over 300,000 EUR in design, manufacturing, installation and testing of FPR prototype, establishment of BLTC, and prefer equity participations through crowd funding as the method of financing, in order to secure credibility for future financing of operations described as above!

ECOPOWER Trust

ECOPOWER Trust is Special Purpose Vehicle (SPV) established for equity funding of this project. It is formatted as the Private Trust, where project’s initiator is Settler, licensed management firm is the Trustee, and donators will be appointed beneficiaries. Current assets (Trust Fund) are:

- Fast Pyrolysis Reactor Prototype, made in Serbia, installed at premise of Serbian BLTC, with over 500 hours of experimental performance;

- SOLID Model and detailed technical documentation (including all manufacturing drawings);

- CFD (Computational Fluid Dynamics) Model;

- Syngas monitoring system utilising the rack mountable analyser measuring CO,CO2, CH4, O2, H2 and CxHx with portable sample probe stainlees steel sample tube;

- 10 metre heated sample line and portable sample conditioning system with integral temperature controller, moisture sensor and sample flow meters, with additional inline filtration due to the use of the rack based analyser;

There are no current or pending liabilities. Donations from Fundraiser campaign will be allocated to the Trust Fund for future benefits of donators.

Upon completed Fundraiser Campaign, ECOPOWER Trust undertakes to:

- Create Serbian company under proposed name PYROPOWER DOO with head office in Cacak;

- Invest donated funds to newly established company as the equity capital;

- Complete the FPR development from prototype to “State of Art” technology within one year from the date of Fundraiser Campaign closing;

- Start with deliveries of standardised FPR devices and settlement of Co-Generation plants through close co-operation with Serbian BLTC and ESCO providers – target is to deliver minimum five FPR devices and to settle five Co-Generation plants with estimated CAPEX of 2.5 M € per plant;

- FPR device market price will not be lower than 300,000 EUR (EXW Manufacturing Unit Serbia) – this policy secures minimum net profit at the range of 400,000 € per annum;

- Net profit will be distributed to Trust Fund for future benefits of Beneficiaries;

- After three years from the date of Fundraiser Campaign closing, ECOPOWER Trust (considering the Will of the donator) will:

- Pay Rewards to donators with amount that includes given donation and accumulated profit, or

- Appoint donators as shareholder of Serbian Company – consideration shall be donated amount increased for amount of accumulated profit;

Rewards Illustration

In respect of hereby given undertakings, donators should consider following illustration of startup potential:

|

Donated Amount |

Rewards (3 years after Fundraiser Campaign closing date) |

|

50 € |

120 € |

|

500 € |

1,200 € |

|

5,000 € |

12,000 € |

|

50,000 € |

120,000 € |

|

500,000 € |

1,200,000 € |

Remark:

Given illustration doesn’t contain any warranty on return or guarantee – it illustrates a business potential of the project, considering the recent business standings, positions, ethic, reputation and references of project initiators.

In addition, ECOPOWER Vouchers are offered for donations over 50 €

For detailed information, please visit www.association-ecopower.com

Rewards

Organizer

- Ivan Tosic

- Campaign Owner

- Belgrade, RS

www.association-ecopower,com

www.association-ecopower,com

No updates for this campaign just yet

.jpg)